General

Lots of brick work now - How many??

Existing liner in run-off recover pond will be completely replaced.

T-rex meets man

There's a guy in that pit. Watch out!

It is standard practice to pour red concrete over all electrical conduits

Piping at Sludge Holding Talk

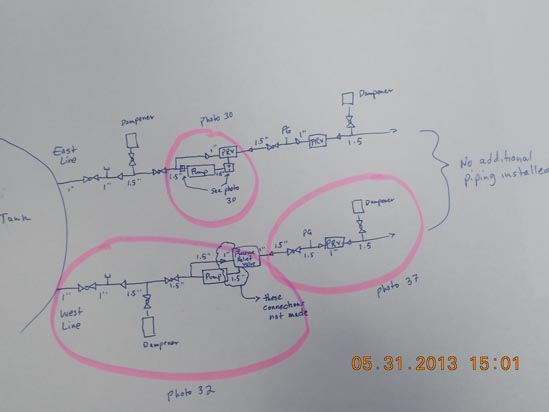

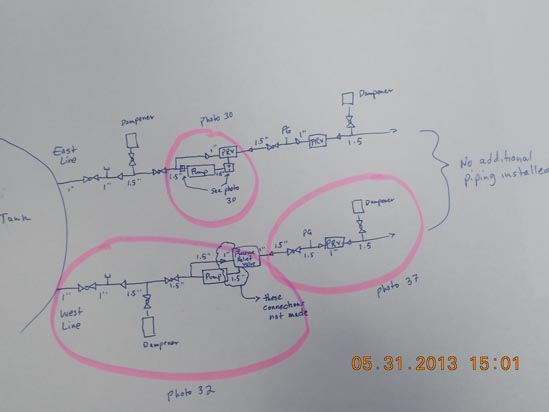

Layout for Vactor Truck receiving station

Conduit vaults at Sludge Storage Tank

Scaffolding set up for coating the emergency storage tank.

Piping for new line feed going to the existing silo. The feed system is being changed from soda ash to lime.

Large construction projects sometimes require mid-course adjustments or clarification.

Big rock in the ground. How do we get this out of here?

Existing manhole before relocation

Rerouting of existing pipe of the original WWTP building

Various yard piping: air, gas, discharge, return lines

Various yard piping: air, gas, discharge, return lines

A tool used to butt weld two ends of gas line.

The coating on the Emergency Storage Tank

The coating on the Emergency Storage Tank

Northeast facing photo of the beginning of the loop road that will circle around the WWTP.

Ron on Donner Summit?? Didn't know we had any of that.

Ron on Donner Summit?? Didn't know we had any of that.

Looking west toward the project on 9/13/12.

A lousy construction day but a beautiful day to ski!

A lousy construction day but a beautiful day to ski!

Line feed pumps will be changed out from soda ash will reduce hardness

Crane lifting structural steel

Spot priming at solids holding tank

Paint preparation at solids holding tank

Exterior horizontal arc welding of equalization storage tank #2

Boilers and recirculation pumps arrive

Boilers and recirculation pumps arrive

Inspecting inside of solids handling tank

Scaffolding for welding wind girder and painting at solids holding tank

Equipment access door for solids holding tank

xray-testing

Control panel at line storage silo

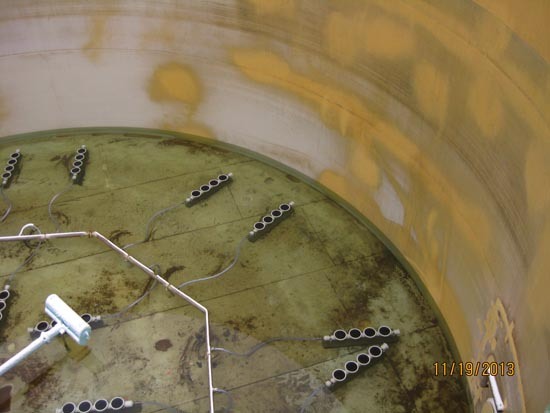

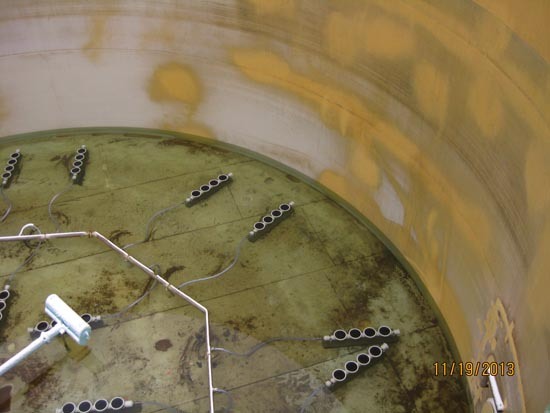

Floor of sludge storage tank prior to being recoated

Erosion control basin at irrigation site

Recoating interior of sludge storage tank

View of sludge storage tank cage to the bottom of the tank

Recoating interior of sludge storage tank

Section of the roof that was removed from the sludge storage tank

Recoating of the existing sludge storage tank level monitoring cage. The old tank was drained and then inspected. The existing roof had corroded necessitating its removal. The new tank can now be decanted which will make it more efficient.

Roof removal of the existing sludge storage tank.

Red concrete is poured over electrical conduit

Installing new fuel tank for the generator

Installing new fuel tank for the generator

Installing exhaust system in generator room

Top of beam for crane rail

Piping and flex coupling

Line of blower units

Fuel maint system

Diesel fuel lines

Conduit installation to damper motor operators

Standby generator breaker and feeds to loadbank

Added 120 volt circuit at generator termination panel

February snow storm blankets diesel fuel storage tank

UV equipment and piping with RAS pumps in front

Installing blower piping for reactors 1 and 2

Organization and installation of solid grating at tanks

PG&E crew pulling new main feed from transformer

PG&E crews removed the feed to the ATB

PG&E arrived for a one day service transfer of main

Crews use 12,500 lb weight to test 5 ton overhead crane.

Working through light snow

Dampers for generator room

March went out like a lion with about 3' of snowfall

Polymer injector assembly for solids conditioning

Polymer skid & injectors for Solids Handling Building

Electrical inspector and SCADA coordinator on alarms at Advanced Treatment building

VFD wire pulled from MCC line up to RAS pumps

12" & 18" vent piping from top of reactor vessels

A screened tent was used to protect SCADA equipment.

Back-pulse tank hold-downs and 3water connection

A snow storm hampered the work on the plant drain pump station.

Setting slide gates and screens at headworks channel

The final bolting and tightening of roof trusses.

The north access road opened up soon after snow.

Plant drain pump station guid rails and pumps

High pressure air and seal water piping in vault

Painters coating interior of plant drain pump station.

Laying out and initial installation of 3 water system

The plant drain pump station construction.

The start of Reactor #2 piping and demo work.

Interior coating of wetwell at plant drain pump station

Installing pipe bracing at structural horizontal beams

A new 6" drain valve replaced the broken plug valve.

Syblon Reid making major modifications at Reactor 2.

Overflow piping north of CI2 basin outlet structure

The demolition of sludge return pump shed at Reactor 2.

Kodiak Roofing was back on-site to install a new metal roof.

Demo work included the removal of baffle at Reactor 2.

Media racks exposed during draining of Tank 2.

Propane Tank located east of the fire station. Tank installation begins in September.

Lower propane storage area and north access road.

The draining of outlet area for Reactor 2 modifications.

New inlet piping across outlet section of Reactor 2

Attaching permeate collection header to pump suction

The removal of media frames from Treatment Tank 2.

PWPS during interior 100% solids epoxy coating

Draining existing Tank 2 for conversion to Reactor 2.

The existing clarifier drained at Reactor 2.

Connection of new OF to CI2 bypass for effluent

Finished painted davit crane bracket welded to bridge

The Chlorine Contact Basin has been removed.

Pouring baffle base wall and columns at Reactor 2

SRC focused on subgrade work at the beginning of the month.

Sludge Tank drained in order to fix the broken aeration system.

The waste activated sludge piping being installed at Reactor Tank #1.

CSE cut the power to the panels in the ATB and is ready for SRC to demo.

The removal of the existing AC in preparation for new paving.

Syblon Reid Company's carpenter is placing lettering on all the new buildings.

Reactor Tank #1 improvements

SRC's subcontractor is hydro-seeding the disturbed area throughout the site.

The view of the new Irrigation Hill. SRC completed more erosion control measures.

Reactor Tank #2 is handling the plant flow while Reactor Tank #1 has work done to it.

SRC's mechanical crew started to demo the filter tank in the new ATB maintenance room.

Syblon Reid Company raised iron and poured concrete collars throughout the site.

Jeffco is painting the walls and will be coating the floor of the blower room in the EQB.

SRC installed bollards throughout the site. This picture shows the core auger they used.

The beams for the new walk bridge at Reactor Tank #1.

Sludge Tank Drained in order to fix the broken aeration system.